Guide To General Rubber Lining And Its Process

Everything in a house, from the water tank to water supply pipes, needs cleaning and maintenance with time. You need to take proper care of such storage materials and tank vessels. Rubber lining is the method to protect the surfaces of metal pipes, vessels, and tanks from corrosion. The storage vessels filled with liquid are prone to corrosion and rubber lining enhances the resistance. You can protect the metal and other equipment from the rubber lining method.

Here are certain guidelines for the general rubber lining process. Keep reading the article for best practices and methods for rubber lining.

- Prerequisite for metal lining

The metal is evaluated and inspected for any other major problems related to cracks, crevices, and pits that may hinder the rubber lining process. Uneven metal surfaces should be found to prevent air expansion. The primer is applied with tack cement before lining and the last rubber sheet is applied at the end. The metal temperature is required to be maintained at 15 degree Celsius and rubber liners require 49 degrees Celsius for proper application.

- Process of primer and cement application

The primer is applied first, followed by some applications that are to be completed before the lining. Tack cement and natural rubbersheet are applied on a particular day. Ensure that the cement should be tacky and solvent free. Maximum adhesion can be obtained by re-cementing the areas left to be lined.

- Guidelines for rubber lining

Unroll the rubber sheets from the warming table and take the required size or shape by cutting the rubber. Tied gum sides should be faced outside during the cementing process. Cut the edges at 45-degree skive to form a seam. In some cases, pre-shrinking is required, unrolling the lining and shrinking before cutting the rubber down to a particular required size. The cement is applied and dried to place a fabric liner on a rubber sheet to align cemented metal.

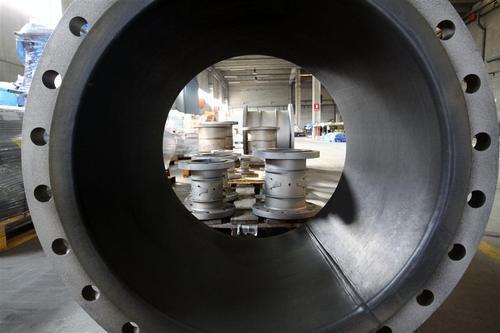

- Rubber lining on pipes

The pipe has to match the requirements in ARPM IP-4-2. Similarly, the requirements should be discussed before the pipe fabrication process.

Metal surfaces are lined and blasted to white metal for final preparation. There shouldn’t be any oxidation. dirt, oil, and other debris over the metal.

- Cementing process

After blasting, a primer with additional coats of cement is applied as per the instructions. Use a roller, swab, and spray to apply primer or cement inside the pipe. Enough drying time should be provided for perfect alignment and cementing.

- Lining a standard flanged pipe

Use skived seams for tube forming and wrap lining stock around the mandrel with the help of a liner. The outside circumference of the tube should be less than the inside circumference. Ensure that the length of the tube should be less than the pipe.

The multifilament cotton strings are applied for air ventilation between the lining and pipes. You should not use synthetic yarn strings. The stringing process should always be done after cementing and equal spacing should be there among individual strings.

Usually, four strings of diameter 6” are used for pipes and more for large pipes. Now, wrap the tube attaching a tow rope in a liner. Pull the tube in the pipe slowly. You can expand the tube after removing the liner and use air pressure against the pipe.

The excess flare stock and extension are removed and trimmed flush with the flange face. Apply a covering over the flange full face and skive flange ID less than the lining ID and stitch the tube stock. Use soft rubber gaskets on flanges when applying hard rubber lining.

The large pipes that are more than 6”, lap the flange stock over the pipe lining lying inside in place of the skive. The lapping method is an appropriate and structurally sound joint for large pipe linings.

Conclusion

There are many more pipes that require a slightly different method for rubber wear liners. You can take a consultation with rubber lining specialists and professionals to know about the perfect method for a particular pipe, tank, or vessel. They can provide you with the right suggestions or pieces of advice based on their years of experience.