Visit the Best Tool And Die Making Rajkot: Novel Mould

What is the tool manufacturing?

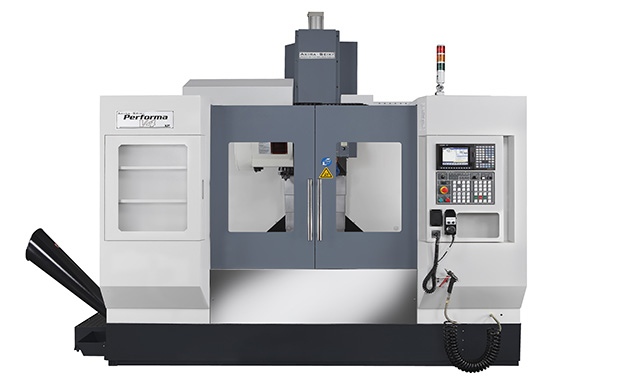

Tool making refers to the assembly of tooling, like cutting tools, metal forming tools, and fixtures, also as machine tools that square measure wont to hold, manufacture, or take a look at product throughout the fabrication method. Tool creating usually needs building custom tools or modifying commonplace tools with the employment of machine tools, like lathes, edge machines, grinders, power tools, honing stones, and files, so as to manufacture merchandise. Tool and die making Rajkot is one-stop solution for all your problems.

What is die manufacturing?

We manufacture our tools in house utilizing high technology like waterjet cutting, wire EDM, CNC machining, and optical profile grinding. we have a tendency to custom fabricate dies for in-house progressive stamping production and conjointly partner with our customers trying to style and manufacture tools to expeditiously integrate in their own in-line automation processes. Tooling fixtures that we have a tendency to manufacture embody checking fixtures, scrutiny gauges, and assembly fixtures.

Forming dies were usually created by tool and die manufacturers and place into production once mounting into a press. The die was a mental block that was used for forming materials like flat solid and plastic. For the vacuum of plastic sheet solely one form was used, usually to make clear plastic containers (called blister packs) for merchandise. Vacuum forming was thought of a straightforward molding thermoforming method however uses identical principles as die forming. For the forming of flat solid, like automobile body elements, 2 elements could also be used: one, known as the punch, performed the stretching, bending, and/or blanking operation, whereas another half that was known as the die block firmly clamps the work and provided similar stretching, bending, and/or blanking operation. The work could tolerate many stages mistreatment totally different tools or operations to get the ultimate type. within the case of associate degree automotive part, there was sometimes be a cutting off operation once the most forming was done so further crimping or rolling operations to confirm that every one sharp edges were hidden and to feature rigidity to the panel.

All about tool and die making

The fabrication of press working dies constitutes the foremost a part of the work wiped out the tool and die, retailers. Most press working dies area units utilized within the fabrication of sheet-metal components that target size from the finger stop on a phone to the panels of the AN automobile body. every press working die consists of 2 sections, known as punch and die, or male and feminine. each section area unit mounted firmly in AN electrically or hydraulically driven press. in a very operating cycle the press ram, on that the male section is mounted, descends into the mounted feminine section. Any metal interposed between the sections is cut or formed to a prescribed type. just like the dies, the presses target size from very little to mammoth. A bench press is usually sufficiently small to be picked up manually; however, the press that stamps out the roof of an automobile are usually regarding 3 stories high and capable of exerting heaps of force.

The tooling concerned in plastic molding is sort of almost like that of stamping dies. The principal distinction is that stamping needs force, whereas molding doesn’t. In plastic molding, 2 units area unit needed whose style is such, once brought along, they create up a system of closed cavities coupled to a central passageway. Liquid plastic is forced through the passageway and into the cavities, or molds, and once the plastic solidifies, the molds open and also the finished components area unit ejected.

Study blueprints, sketches, specifications, or CAD (CAD) or computer-aided producing (CAM) files for creating tools and dies to Compute and verify dimensions, sizes, shapes, and tolerances of work pieces Set up, operate, and destroy typical, manual, or pc numerically controlled (CNC) machine tools File, grind, and regulate elements in order that they work along properly Test completed tools or dies to confirm that they meet specifications Inspect for correct dimensions and defects Smooth and polish surfaces of tools and dies

Thus all of the above information provided must be very useful for you. Visit Novel Mould tool and die making Rajkot for all your tool and die related solutions.

Tool making refers to the assembly of tooling, like cutting tools, metal forming tools, and fixtures, also as machine tools that square measure wont to hold, manufacture, or take a look at product throughout the fabrication method. Tool creating usually needs building custom tools or modifying commonplace tools with the employment of machine tools, like lathes, edge machines, grinders, power tools, honing stones, and files, so as to manufacture merchandise. Tool and die making Rajkot is one-stop solution for all your problems.

What is die manufacturing?

We manufacture our tools in house utilizing high technology like waterjet cutting, wire EDM, CNC machining, and optical profile grinding. we have a tendency to custom fabricate dies for in-house progressive stamping production and conjointly partner with our customers trying to style and manufacture tools to expeditiously integrate in their own in-line automation processes. Tooling fixtures that we have a tendency to manufacture embody checking fixtures, scrutiny gauges, and assembly fixtures.

Forming dies were usually created by tool and die manufacturers and place into production once mounting into a press. The die was a mental block that was used for forming materials like flat solid and plastic. For the vacuum of plastic sheet solely one form was used, usually to make clear plastic containers (called blister packs) for merchandise. Vacuum forming was thought of a straightforward molding thermoforming method however uses identical principles as die forming. For the forming of flat solid, like automobile body elements, 2 elements could also be used: one, known as the punch, performed the stretching, bending, and/or blanking operation, whereas another half that was known as the die block firmly clamps the work and provided similar stretching, bending, and/or blanking operation. The work could tolerate many stages mistreatment totally different tools or operations to get the ultimate type. within the case of associate degree automotive part, there was sometimes be a cutting off operation once the most forming was done so further crimping or rolling operations to confirm that every one sharp edges were hidden and to feature rigidity to the panel.

All about tool and die making

The fabrication of press working dies constitutes the foremost a part of the work wiped out the tool and die, retailers. Most press working dies area units utilized within the fabrication of sheet-metal components that target size from the finger stop on a phone to the panels of the AN automobile body. every press working die consists of 2 sections, known as punch and die, or male and feminine. each section area unit mounted firmly in AN electrically or hydraulically driven press. in a very operating cycle the press ram, on that the male section is mounted, descends into the mounted feminine section. Any metal interposed between the sections is cut or formed to a prescribed type. just like the dies, the presses target size from very little to mammoth. A bench press is usually sufficiently small to be picked up manually; however, the press that stamps out the roof of an automobile are usually regarding 3 stories high and capable of exerting heaps of force.

The tooling concerned in plastic molding is sort of almost like that of stamping dies. The principal distinction is that stamping needs force, whereas molding doesn’t. In plastic molding, 2 units area unit needed whose style is such, once brought along, they create up a system of closed cavities coupled to a central passageway. Liquid plastic is forced through the passageway and into the cavities, or molds, and once the plastic solidifies, the molds open and also the finished components area unit ejected.

Study blueprints, sketches, specifications, or CAD (CAD) or computer-aided producing (CAM) files for creating tools and dies to Compute and verify dimensions, sizes, shapes, and tolerances of work pieces Set up, operate, and destroy typical, manual, or pc numerically controlled (CNC) machine tools File, grind, and regulate elements in order that they work along properly Test completed tools or dies to confirm that they meet specifications Inspect for correct dimensions and defects Smooth and polish surfaces of tools and dies

Thus all of the above information provided must be very useful for you. Visit Novel Mould tool and die making Rajkot for all your tool and die related solutions. Get in touch with us.